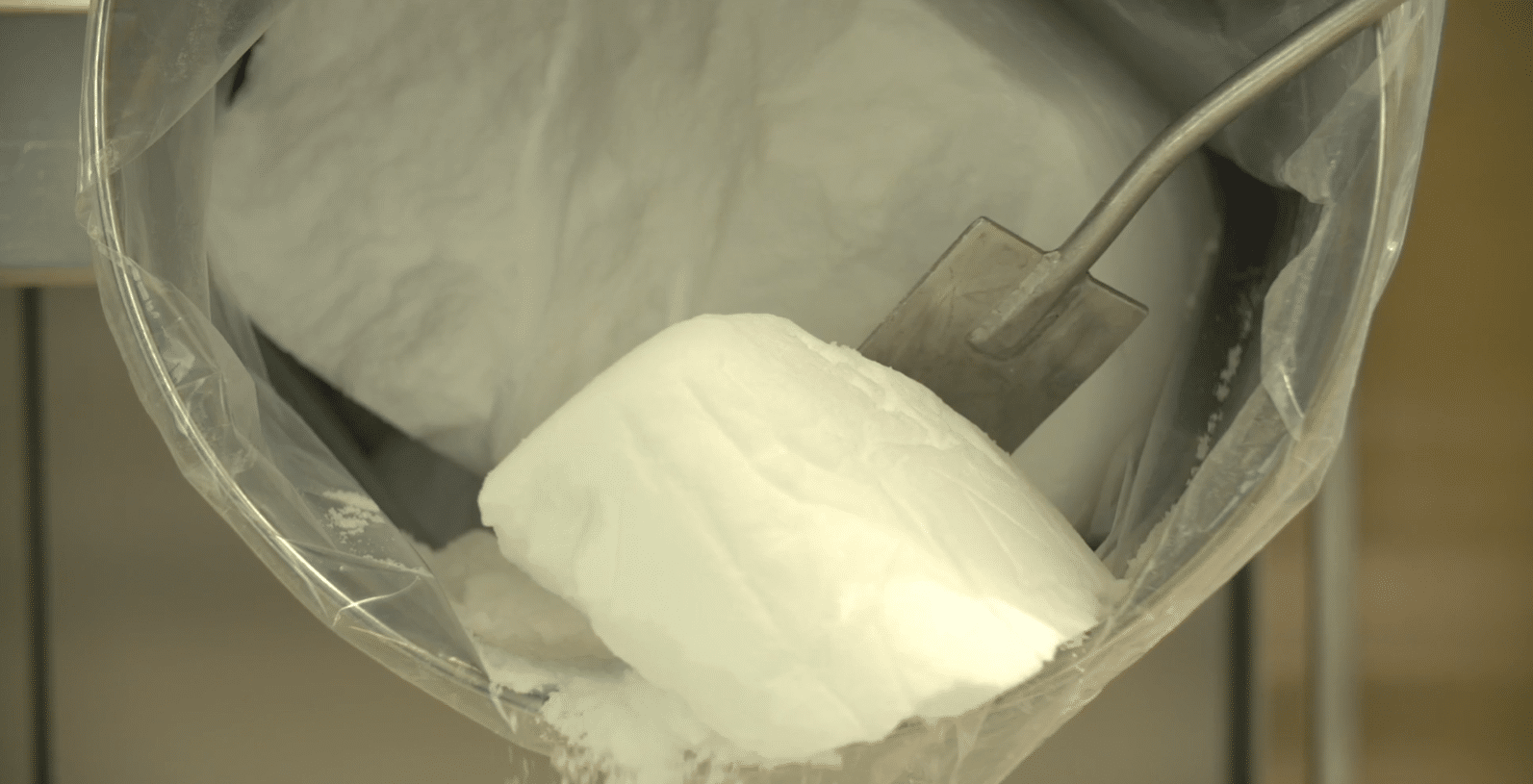

It’s a familiar scenario: opening a package of bulk material that’s been in storage for a while only to find it has formed clumps, caked together, or – at worst – even completely solidified. A lot of biopharma businesses have learned to simply deal with this irritation. The question is, can they afford to – and is there any way to avoid it?

During biopharmaceutical manufacturing, buffers, salts, and stabilizing chemicals are used in multi-ton quantities. Handling bulk powders on this scale can be a real challenge, and a lot depends on the plant’s schedule and capacity. During storage, compounds like potassium chloride, glycine and urea – commonly used to prepare buffer solutions – naturally cake and solidify due to their chemical properties, which can make them even more difficult to handle on this scale. The level of caking can be hard to predict before opening, as it depends on the transport and storage conditions. Dust formation and laborious weighing further hamper manufacturing efficiency, and can even delay or interrupt processes, impede quality, and pose safety risks to operators.

Caking costs

All of this has an economic impact that you’d think would be obvious but is all too easy to overlook. For businesses that rely on just-in-time, flexible handling of chemical raw materials, delays are not an option – speed, flexibility, quality and cost are paramount. Manually de-caking solidified blocks of bulk powder wastes valuable time and poses a serious risk of injury to the operator. When products are caked, emptying the primary packaging is made that much more difficult, sampling and weighing are almost impossible, and then there’s the risk of process delay or interruption. As a result, total cost of ownership can greatly increase.

Unfortunately, current anti-caking solutions tend to be inadequate and time-intensive, merely addressing the symptoms without preventing caking in the first place. This is especially the case for chemicals prone to heavy caking. Avoiding prolonged storage is one option, but this can be difficult to ensure. What if there were a technological solution to the caking challenge?

Going granular

Switching to granules can be a way to avoid disruptions and keep operating costs low. Compared to bulk powders, granulated materials have better flowability and are easy to handle, with far less caking, even after long-term storage. Any small clumps that may occasionally emerge can be easily broken up – a far cry from the intense caking of many bulk materials, which can often even solidify into a single giant block. Thanks to their material properties, granules offer better processability, speed up manufacturing processes and improve operator safety.

In particular, dry-granulated raw materials that have been compressed by roller compaction show a number of advantages over bulk. As the compaction process relies on compression force only, no liquid or binders are needed, meaning there’s no change in the chemical composition and the characteristics of the raw material are preserved. In roller compaction, the material is simply compressed into plates or sheets between two rotating rollers, and these plates are then milled into granules. Compared to other compaction methods like slugging, this form of dry granulation is very gentle, making it especially appropriate for heat- and moisture-sensitive materials. As a result, roller compaction creates granules with excellent integrity and very low abrasion rates, so they’re exceedingly stable during transport and storage. When it comes to preparing the buffer, their dissolution behavior is comparable to bulk material – although the dissolution kinetics of granules can be slightly longer, their better handling characteristics more than outweigh the additional time needed for dissolution.

Need for speed

In dynamic production environments subject to tight time pressures, this seemingly small change may make a surprising difference. The ease of handling granulated materials helps ensure a lean, robust workflow – making things easier for operators – as well as facilitating rapid changeover of chemicals ready for the next manufacturing process.

You can learn more about the benefits that granulated raw materials demonstrate over bulk powder in this scientific poster we’ve prepared.