| The integration of Raman spectroscopy with an automated feedback loop has transformed biopharmaceutical manufacturing. This innovative approach enables real-time monitoring and precise maintenance of glucose levels in cell cultures, ensuring optimal process quality, product yield, and glycosylation. Traditional manual sampling and feeding of bioreactors are not only costly and time-consuming but also pose a significant risk of contamination each time the sterile boundary is breached. However, the implementation of Raman spectroscopy as a process analytical technology (PAT) tool for in-line monitoring offers an excellent solution to gain real-time insights on glucose levels in the bioreactor, allowing for swift reactions to changes while minimizing contamination risks.

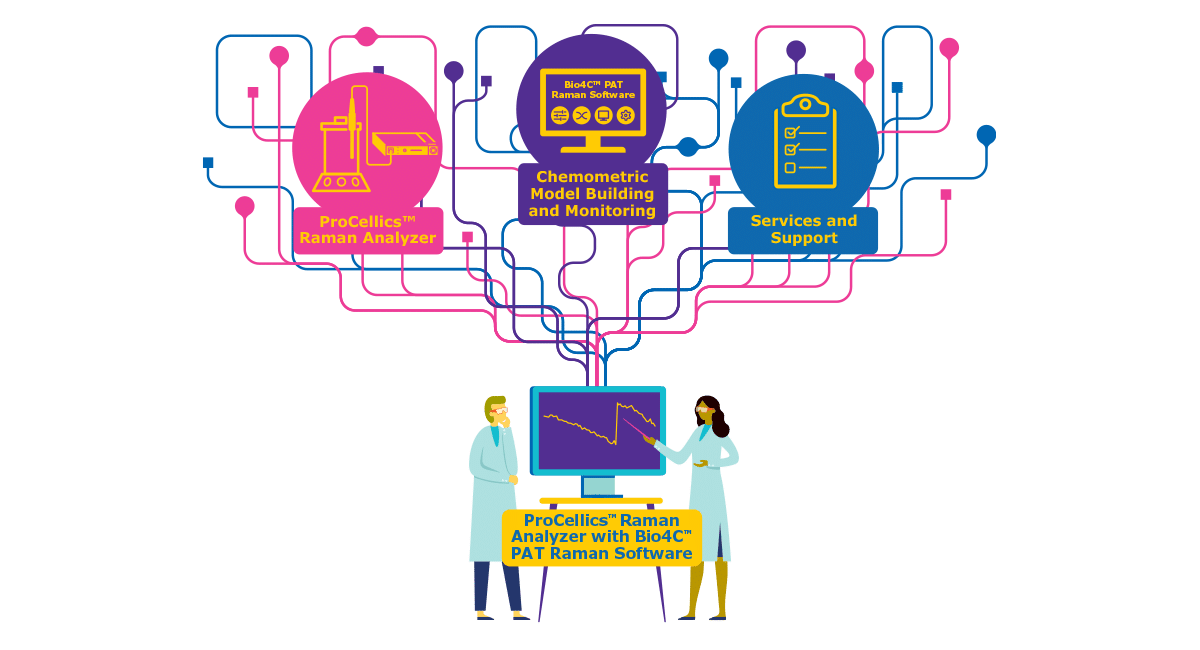

In a case study, we implemented a feedback control loop in a CHO cell culture process and used a ProCellics™ Raman Analyzer with Bio4C® PAT Raman Software to monitor glucose concentration. This approach enabled the maintenance of stable glucose levels without the need for manual intervention, leading to improved process quality and supporting proper glycosylation of the product. The successful integration of Raman spectroscopy with an automated feedback loop represents a significant advancement in biopharmaceutical manufacturing, driving a new era of excellence in the industry. This transformative solution not only enhances process efficiency and product quality but also ensures reliable, real-time process control, empowering users to navigate upstream biopharmaceutical manufacturing with confidence. To learn more about the integration of glucose control in CHO culture via Raman spectroscopy, read our technical article here. |