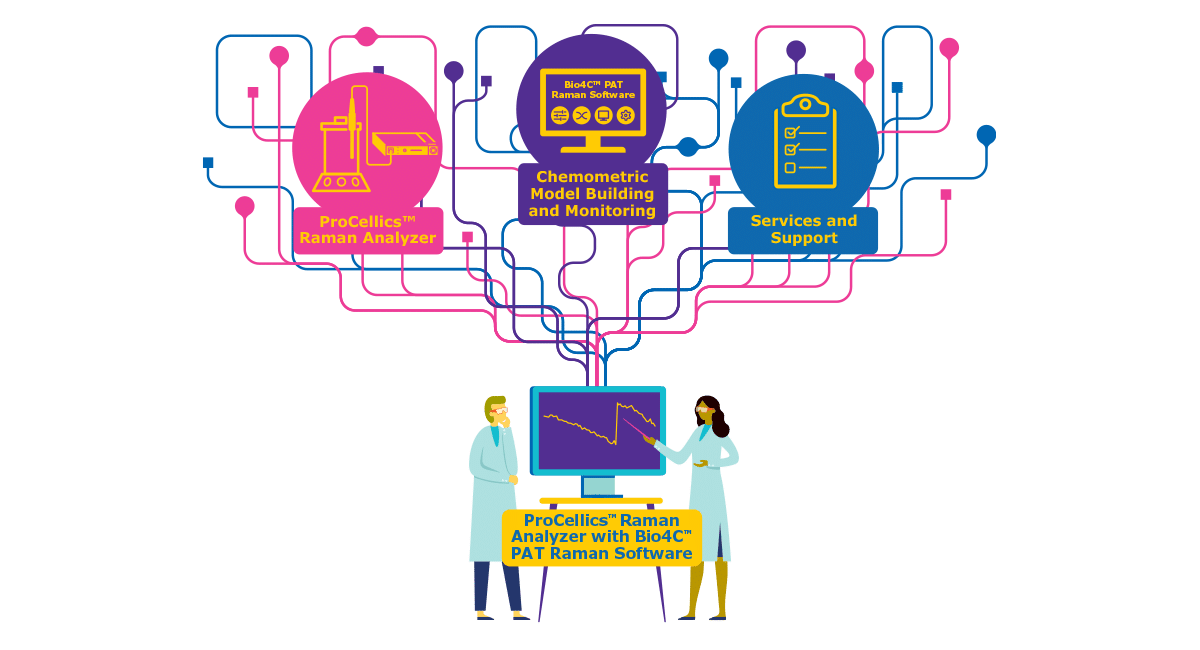

Process Analytical Technology (PAT) plays a pivotal role in ensuring quality throughout biopharmaceutical manufacturing by enabling real-time monitoring and control of processes. By utilizing analytical tools, PAT enables the development of manufacturing processes that can accommodate variations in materials and equipment. Through the identification of critical process parameters (CPPs) that affect critical quality attributes (CQAs), analytical methods are employed to continuously monitor and regulate these CPPs, keeping them within the desired design space. This approach integrates quality by design (QbD) principles into the manufacturing process, prioritizing proactive control rather than relying solely on end-product testing for quality assurance.

To learn more about PAT, watch part 1 of this 4-part “Meet the Experts” interview series to learn about PAT in bioprocessing, the importance of implementing a PAT strategy, and more from expert Stacy Shollenberger by clicking here.