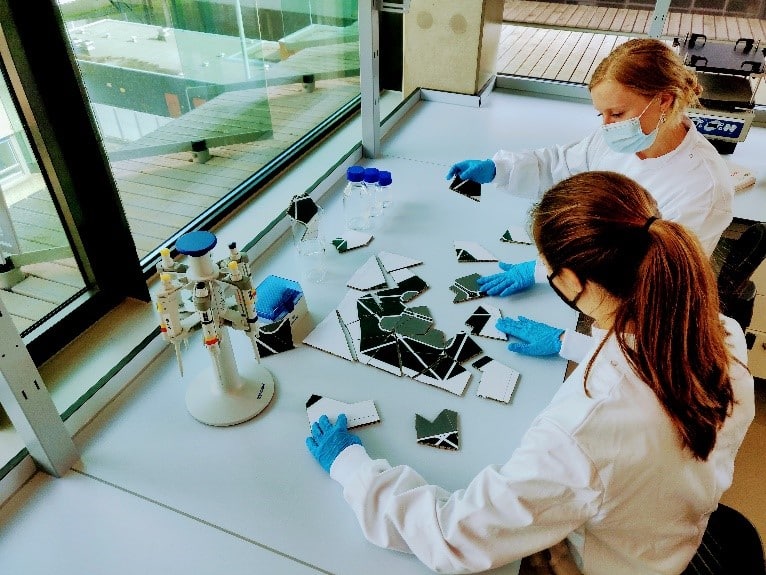

Having both recently graduated from our Masters degrees, Christina in Neuroscience from ETH Zürich and Charlotte in Chemistry from The University of Edinburgh, our first days at VectorY were certainly puzzling; new faces, busy schedules, lots to learn and lots to do. Since VectorY is a start-up, founded in October 2020, we are not the only new additions to the company. For us, both Junior Technicians, and the least experienced members of the team, building up our understanding of VectorY has been like putting together the pieces of a jigsaw having never seen the final image on the puzzle box. Supported by the team of highly skilled experts: molecular and structural biologists, protein chemists, immunologists, virologists, translational scientists and process engineers, who together bring many years of combined industry and research knowledge, it has been possible for us to apprehend the goals and mission of VectorY.

VectorY is an Amsterdam based gene therapy company specialising in the development of vectorized antibodies to treat diseases of high unmet medical need, with a specific focus on muscle and neuromuscular diseases. Despite the limited number of approved gene therapies, progress within the field has been remarkable over the past few years and many new companies have emerged. It is therefore not unreasonable to ask, what makes VectorY stand out from the rest? In rethinking our approach to the development of gene therapy treatments we have established three integrated pillars on top of which the company was founded by a group of gene therapy enthusiasts and Forbion, a leading European venture capital firm, as the founding investor.

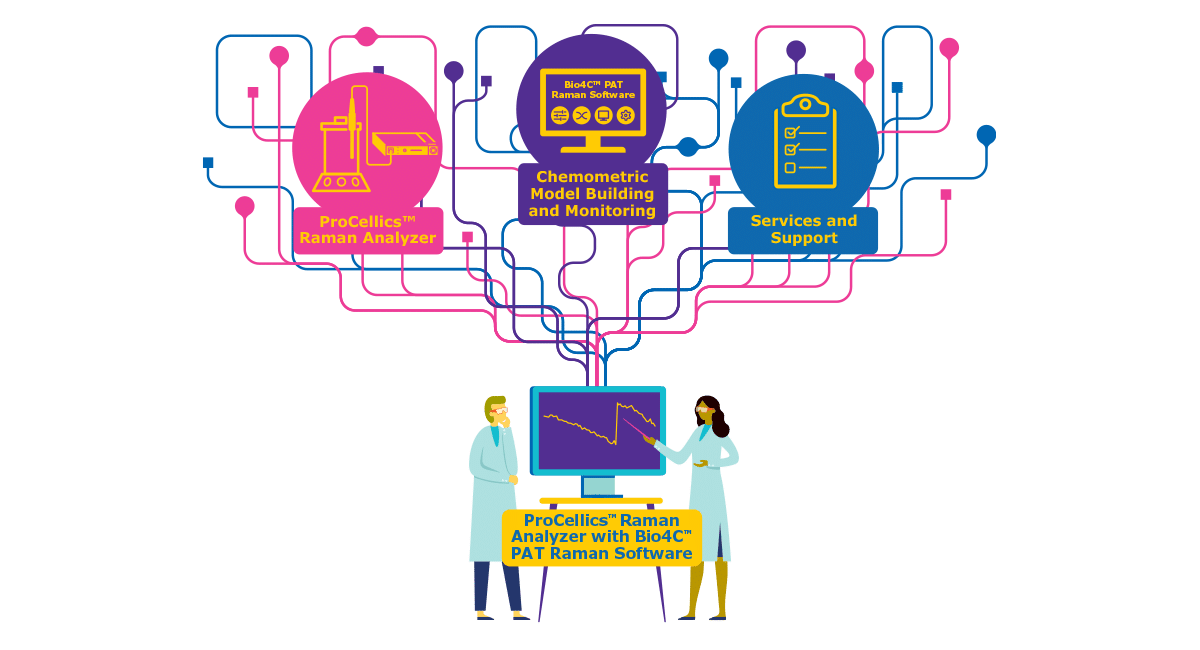

The first of these pillars is research. This department works on disease-targeting and the development of innovative vectorized antibodies, pushing the limits of current therapies in terms of delivery, durability and target accessibility. The second pillar is vector development, where vehicles to deliver the therapy developed by the research team are constructed and optimized. The aim of the vector development team is to target different cell types and sub-cellular compartments in a highly specific manner whilst evading the host immune response. The final pillar, manufacturing, focuses on advanced manufacturing technologies for the cost effective production and scale up of viral vectors. We also intend to build a manufacturing facility where our gene therapies will be produced using optimized production processes resulting in shorter timelines and lower cost of goods.

One fundamental aspect of the VectorY model is to establish a facility with dedicated laboratories rather than operating as a virtual company and contracting out large amounts of work. This allows for reduced timelines and greater control over our research and processes ensuring we continue to drive development in the right direction. Early investment in manufacturing also helps to minimize longer term risks associated with potential capacity shortages. In addition to this, by gathering a team of experts on site we strive to foster innovation. Social distancing measures have made cultivating a sense of community between the team more challenging than in pre-pandemic times. Creative alternatives to team building activities, such as our game of online bingo, have been adopted and enjoyed, strengthening a spirit of collaboration within the team.

Start-ups must always navigate many obstacles but launching a biotech company in the midst of a pandemic has presented many unique challenges. From identifying where to install new power sockets to removing fume hoods, coordinating such activities has been an expected, though entirely new undertaking for the team. Of paramount importance was the implementation of a system to account for the great quantities of packages arriving every day, sometimes filling the lift from floor to ceiling. As the labs have filled with equipment and consumables, keeping track of what is on site, what is incoming and what is still needed has been an enormous undertaking. Where the classical start-up lifecycle starts in a single workspace, we got a head start by having access to multiple laboratories and offices at our disposal. Notably, within six months our previously empty labs and offices have been transformed into fully operational offices and laboratories with the latest technologies needed for scientific discovery.

Furthermore, due to the pandemic and unfortunate global supply chain disruptions, much of the equipment and consumables we use in our processes are in high demand, resulting in long lead times. The pipette tips that are an essential component of virtually every experiment we do are also crucial disposables for the huge numbers of Covid-19 tests being carried out worldwide. The material used in the production of these tips, as well as various tubes used for experiments, has also proven hard to obtain due in part to incredibly high demand but also as a result of extreme weather conditions impacting production at a major manufacturing site in the U.S. In addition to this, securing the bioprocess equipment and consumables we require to run our 50 L pilot scale process has been more challenging than in pre-pandemic times. This equipment is used to manufacture Covid-19 vaccines and lead times can be upwards of six months. Sourcing vital equipment can, at times, feel like we are assembling a jigsaw whose pieces are scattered across the entire world.

Despite the difficulties associated with start-ups, and the additional hurdles presented by the pandemic, we continue to make steps towards our goals and this is truly exciting. Additional support provided by

References:

VectorY website: https://www.vectorytx.com/

Launch of VectorY, press release: https://www.vectorytx.com/press-releases

With a roster of gene therapy vets, Forbion makes a bet on ‘relatively empty space’ of vectorized antibodies, February 10, 2021 (Endpoints article): https://endpts.com/with-a-roster-of-gene-therapy-vets-forbion-makes-a-bet-on-relatively-empty-space-of-vectorized-antibodies/

Forbion website: https://forbion.com/en/

Launch of novel gene therapy company, VectorY, to develop innovative vectorized antibodies, February 10, 2021:

The Latest Supply Chain Disruption: Plastics, March 26, 2021: https://hbr.org/2021/03/the-latest-supply-chain-disruption-plastics

https://www.merckmillipore.com/NL/en/20210517_173115?ReferrerURL=https%3A%2F%2Fwww.google.com%2F

VectorY at ASGCT 2021: https://www.vectorytx.com/news/vectory-presents-at-asgct-2021